Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

Intralogistics systems play an important role in the automated in-plant transport of materials in factories, distribution centers, parcel services, warehouses, airports, hospitals, and others. These systems increase efficiency, quality, sustainability, and traceability of material flow processes, while reducing waste and inventory buffers. Without them, modern high performance facilities could not function. Electrification components are needed for intralogistic equipment as Automated Guided Vehicles ( AGV), Electric Monorail Systems ( EMS), electric pallet conveyors, rail guided vehicles (RGV), transfer cars, and baggage handling systems, as well as sorters, automated storage and retrieval systems (AS/RS, stacker cranes) and shuttle systems.

Intralogistic systems must be available on demand. If part of the system goes down, processes before and after will stop and the entire facility could shut down. Also, any required maintenance must be done quickly and easily. Energy and data transmission components must adapt to high performance systems, often with complex layouts and operating at high speeds and acceleration. At the same time, they must provide maximum energy efficiency at an acceptable cost. Some systems must meet special technical challenges, such as “clean room” and food processing environments, refrigerated storage, or impure production lines.

Conductix-Wampfler has extensive experience working with intralogistics system OEMs worldwide. From our large product portfolio, we can recommend the optimum solution for individual applications across many different industries without bias towards single technology. With our global presence and local support, we partner closely with OEMs and end-user customers for both small and large scale projects, striving for technical optimization with minimum complexity. Our continuous research & development efforts are geared towards new solutions and continuous improvements of products for this industry.

Inductive Power Transfer (IPT) – powers systems such as AGVs and baggage handling systems. New generations of IPT with state-of-the-art features keep pace with our customers needs.

Conductor Rails – power Electrified Monorail Systems ( EMS), Rail Guided Vehicles (RGV), and baggage handling systems. The SinglePowerLine 0812 and MultiLine 0831, combined with ProShell are ideal for AS/RS stacker cranes. MultiLine 0835 and MultiLine 0365 are the perfect match to power shuttle systems. PEplus for conductor rails works well for electric conveyors of all types, providing safety and simplicity.

Spring-Driven and Motor-Driven Reels – manage cables used to power transfer cars and other moving equipment.

Rubber and Cellular Buffers – are well suited to absorbing energy from machine element impacts.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of intralogistic applications.

Aplicación

Carro de transferencia de bobinas de acero

País

Francia

Ciudad

Reims

Oficina del representante

Conductix-Wampfler (F)

Operador

ArcelorMittal PUM

Requisitos técnicos

Transmisión de energía eléctrica y de datos para un carro de transferencia

Producto/s

IPT® (transmisión inductiva de energía), iDAT

Captor/es

1 (captor en forma de F de 7x2,2 kW 560 V + 1x750 W 560 V)

Longitud (sistema)

125 m

Cantidad de (carga)

1

Distancia de trayecto (carga)

125 m

Velocidad de trayecto (carga)

20 m/min

Condiciones medioambientales

Estructuras de acero

Dirección del sistema

Recta

Información adicional

iDAT (transmisión inductiva de energía)

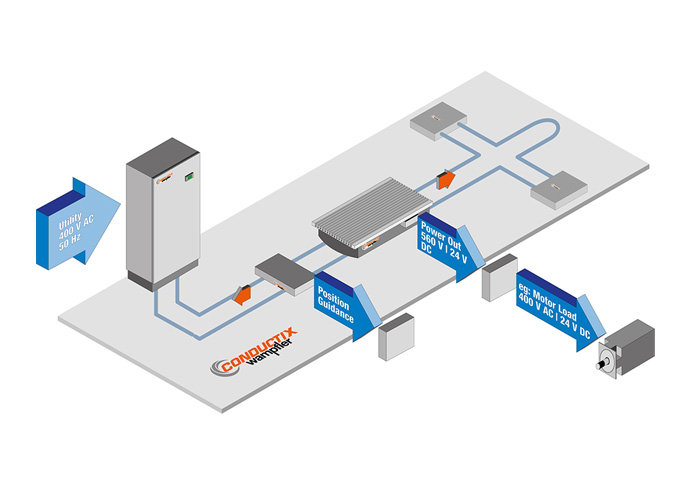

Generally the basic function of Floor systems is the same as that of other Inductive Power Transfer systems. But there are some additional or specific aspects to consider.

The cable loop must be installed in a way that complete coverage of the supply of vehicles along the entire travelling path is given. This way installed the cable routing also defines the travelling path of vehicles. With inductive track guidance it is possible to detect the magnetic field around the cabling and to supply a guidance signal to the vehicle control and to control so the movement of the vehicle. Unwanted and expensive guidance slots become obsolete this way. Various travelling paths can be defined. Switches, crossings, etc. are no problem. The pickup just needs to be placed so that it is exposed to the magnetic field in a sufficient way.