Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

Conductor bar is a safe and economical method to provide electric power to mobile equipment. We were the first to offer "8-bar" insulated conductor bar for crane electrification in the US back in 1952. Now you can choose from six unique systems for virtually any need from 100 to 1500 amperes and more. We've manufactured the brands you have trusted for the past 60 years: Insul-8, Wampfler, and Saf-T-Bar - now part of the Conductix-Wampfler conductor bar family.

Now you can choose from six unique systems for virtually any need from 100 to 1500 amperes and more. We've manufactured the brands you have trusted for the past 60 years: Insul-8, Wampfler, and Saf-T-Bar - now part of the Conductix-Wampfler conductor bar family.

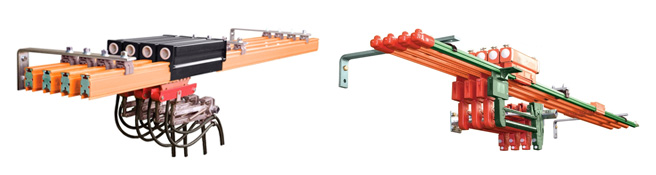

SAFE-LEC 2 ® V-Contact Conductor Bar System - the new standard in overhead crane electrification. SL 2 is ideal for monorail and material handling system electrification as well.

Safe-Lec 2 provides these great benefits:

Safe-Lec 2 is easy to install

Curved Systems:

60" minimum radius; factory curved

Current Capacity Range:

100 amps, 125 amps, 200 amps, 160 amps, 250 amps, 315 amps, and 400 amps capacities (600 volts max.)

Maximum Speed:

1,200 feet per minute (365.8 meters/minute)

OPTIONS:

The Conductix-Wampfler Hevi-Bar II Conductor Bar System delivers the kind of reliable, high-capacity crane rail electric service needed by factories, mills, storage yards, people movers, and other rigorous applications.

Hevi-Bar II features:

Current Capacity Range:

500 amps, 700 amps, 1000 amps, and 1500 amps, at 600 volts.

Maximum Running Speed:

2,000 feet/minute (609.6 meters/minute)

OPTIONS:

DURA-COAT - For Corrosive Environments

Hevi-Bar II is available with our optional DURA-COAT finish. Dura-Coat is a specially formulated coating that combines a ceramic compound with an epoxy binder to provide superior corrosion resistance and adhesion to the base materials. The entire bar is coated except in the stainless steel collector shoe running area; the insulating cover is applied over the coating.

All metal parts of the collector arm are coated. Arms are not coated as they are made from high-strength glass filled polymer.

DURA-COAT is an ideal conductor bar for galvanizing and electro-plating lines, chemical plants, smelters, foundries and cast houses, coke and ore handling cranes, and oxidizing/electro-winning facilities.

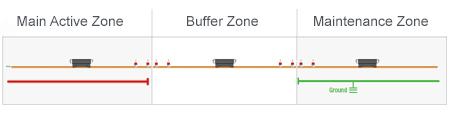

The Conductix-Wampfler PowerGuardTM system is an engineered solution for removing power from a section of your conductor bar without having to shut down your entire runway. This system is perfect for runways with multiple cranes. You can safely service one crane and still keep your other cranes running.

The PowerGuardTM switching system combined with Power Interrupting Sections create an electrically isolated and safe maintenance zone that is designed to never accidentally re-energize - keeping you and your machine safe and protecting your investment.

PowerGuardTM features:

Current Capacity Range:

100, 200, 400, 600, 800, 1200, and 1600 amps

Material handling systems, automated overhead cranes, and other automated machinery often need an accurate way to determine the exact position of the moving machines or elements. You can use this information to assure correct vehicle spacing, provide material storage locations, or to give position feedback. The Conductix-Wampfler Optical Positioning System (OPS) offers a complete solution to supply the needed position information along a fixed rail. You can integrate our OPS into new installations or easily retrofit it onto existing applications.

The Optical Positioning System:

60 years ago Conductix-Wampfler, under the name Rucker Insul 8® Corporation, was the first to develop the original "8-Bar" electric conductor bar. This innovative design greatly improved the safety of overhead crane electrification. Since then, hundreds of miles of 8-Bar systems have been installed and are in use all over the world. It is truly the industry standard!

Conductix-Wampfler Insul 8® 8-Bar Systems are:

Current Capacity Range:

40 amp, 90 amp, 110 amp, 250 amp, 350 amp, and 500 amp capacities at 600 volts max.

Maximum Running Speed:

900 feet/minute (274.3 meters/minute)

Options:

Conductix-Wampfler Side Contact Conductor Bar is a variation of the 8-Bar system designed for lateral (side) entry of the collector. UL / CSA listed. Side Contact is ideal when there is insufficient room for standard "bottom entry" mounting and/orconductors must be more closely spaced than standard 8-Bar allows.

Side-Contact Conductor Bars:

Current Capacity Range:

40 amps, 90 amps, 110 amps, 250 amps, and 350 amps

Maximum Running Speed:

900 feet/minute (274.3 meters/minute)

Factory installed covers are available in: