Orders for 5,000 meters of ProfiDAT

Various solution variants to equip STS container cranes, process cranes as well as E-RTGs

The compact solution for transmitting high data rates through conductor-rail systems for E-RTG and STS cranes catches on.

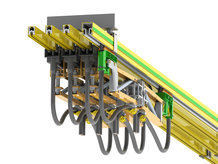

August 2016. Conductix-Wampfler, one of the world's leading manufacturers of systems for energy and data transmission for mobile machinery, offers crane manufacturers with ProfiDAT®, a compact data transmission solution at high data rates over conductor rail systems. No additional construction space is needed, because the combined data-transmission system unifies a data-transmission channel with a conductor-rail profile that can be used as a ground conductor rail. The solution has been well received by the market: More than 5,000 meters of ProfiDAT® profiles have already been ordered until July 2016. Using various solution variants, Conductix-Wampfler can equip STS container cranes, process cranes as well as E-RTGs (electrified rubber-tired gantry cranes).

With a data transmission rate of up to 100 Mbit per second, a real-time channel for PROFINET safety signals (PROFIsafe) as well as audio and video transmission via Ethernet, ProfiDAT® serves the increasing demand for the transfer of ever larger amounts of data and control signals in real time as part of the increasing automation of container ports and crane systems. ProfiDAT® can be used license free anywhere in the world, and is at the same time very easily integrated into existing systems.

Transmission of data from up to 21 cameras in a single ProfiDAT® profile

"In E-RTGs, the protective earth (PE) integrated into the transmission profile permits the conversion of an existing conductor rail configuration to an integrated energy and data transmission solution without any added space requirement," says Dominik Kübler, Product Manager for ProfiDAT® at Conductix-Wampfler. The combined slotted waveguide profile with the three parallel conductor-rail phases form the basic supply unit for E-RTGs. The special feature: Several cranes transmit video and data signals through a common data profile. Thus, up to seven cameras per crane and three cranes in total can be connected to the control center via a single ProfiDAT® profile. “After successfully completing tests at various crane manufacturers with several consumers on our ProfiDAT® system, we soon received orders from Asia, Europe and North America,” says Kübler.

Test phase successfully passed in China

After trials on the in-house test facility at Conductix-Wampfler in Weil am Rhein in 2014, the system solution was first installed on an STS container crane as an alternative to cable chains at a customer in China in February 2015. On STS container cranes, ProfiDAT® is installed in parallel with existing conductor-rail systems, or the PE conductor rail is replaced with the combined ProfiDAT®-and-PE solution. The ProfiDAT® antenna is guided through the PE conductor contacts, moving within the closed profile to permit contact-free, interference-free data transmission. The transmitter and receiver communicate with one another and each have a standard Ethernet interface to permit communication between the transceivers of the stationary crane gantry and the moving crane trolley of an STS container crane. A transition element is installed at the hinge point to provide seamless data transfer to the boom.

“In the test phase at our customer in China, there was a particular focus—in addition to the reliability and security of the transmission of high data rates—on the transition to the boom and on the travel speed,” explains Claus Burger, Global Market Manager for Container Handling at Conductix-Wampfler. With encouraging results: At 210 meters per minute, the trolley speed of the crane is well below the potential travel speed with ProfiDAT®. It should also be mentioned that the solution has since been proving itself under the very demanding climatic conditions in China. This robustness combined with low wear also distinguishes ProfiDAT®,” says Burger with pride. Apparently, word has spread through the market about the positive features, such as no additional installation space requirement, quick installation times, few wear-and-tear items and the price advantage compared to two separate rails, and further orders have resulted.

An important partner for the crane industry

With 5,000 meters of ProfiDAT® profiles ordered to date, Conductix-Wampfler has confirmed its role as an important partner of the crane industry for systems. In addition to solutions for STS and E-RTG cranes, the company also offers ProfiDAT® systems for process cranes. The company has long since made a name for itself in the electrification of RTGs. The new LASSTEC® twistlock container weighing system is another innovative Conductix-Wampfler product for the crane industry. It reliably measures container weights and offers terminal operators additional benefits.